ASTM A532 Class II, Type B High Chromium Cast Iron (HCCI) with 14-18% Cr content is one of the high demand cast irons for abrasion application. Nickel content of these categories can increase up to 2.5%.

This category is the main heat treatable high chromium cast iron that can reach the highest hardness and abrasion by phase transformation of the austenite to martensite.

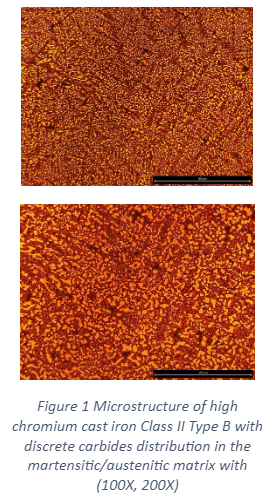

With proper melt treatment and subsequent heat treatment it is possible to achieve a high hardness for abrasion resistance with a high chromium carbide ratio. The toughness is an important differentiator of this category as it naturally tends to be brittle and shows low toughness due to it having a high volume of interconnected chromium carbides. Abreco® uses its expertise to manufacture this category of HCCI with discrete chromium carbides in the martensitic / austenitic matrix. The austenite ratio to martensite is another main factor for this purpose and inline controls by x-ray diffraction (XRD) techniques. This enables Abreco® to guarantee the maximum toughness with presence of high volume of discrete chromium carbides.

While austenite improves the impact resistance of HCCI, it also reduces the abrasion resistance and increases the spalling ratio in abrasive materials. The addition of molybdenum improves the hardenability and is typically used for thicker sections that require heat treatment.

Lower Cr content on this material reduces corrosion resistance properties as well as wear resistance and is usually used for higher impact applications.

Unlike other high chromium cast iron, Abreco’s modified HCCI’s have a combination of the highest toughness and abrasion resistance by precisely controlling the chemistry and production process. Figure-1 shows the high chromium cast iron after heat treatment with uniform discrete chromium carbides in the martensitic matrix.

In modified HCCI’s, the chromium carbides have been transformed from (M)Cr3C to (M)Cr7C3 and (M)Cr23C6 structure and other complex high Cr content crystalline form with higher toughness and round ended shapes.

Discontinuous chromium carbides in the matrix with round ended shape increase the fracture toughness of HCCI by reducing stress concentration factors at the carbide’s tips.

The other type of HCCI is laminated high chromium cast Iron (LHHCI) which is metallurgically bonded with a steel substrate. This technology increases the impact resistance of the HCCI as well as prevents the cast from fracturing. The strength of bonding is equal to the rupture stress of the steel and easily withstands shear failure.

All grades of laminated HCCI are suitable for TIG, MIG and SMAW welding for high wear and high impact application.

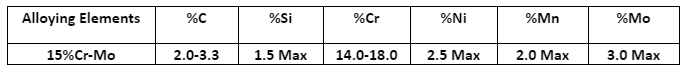

Chemical Composition (ASTM A532-II B)

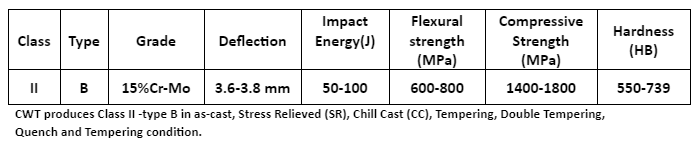

Mechanical and Physical Properties

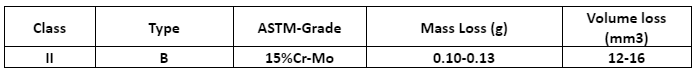

Wear and Abrasion Resistant Properties

Application:

High chromium cast iron Class II Type B is a heat treatable alloy in this category and can achieve a wide variety of hardness and toughness through heat treatment. Due to the wide range of mechanical properties this category has extensive application in the industry in the as-cast and as-heat treated condition. For high abrasion and low impact application preferably use the low Cr/C ratio alloys such as conveyor liners, chute walls, screens, brick moulds, coal grinding mills, grizzly fingers, shot blast equipment, quarry components, hard-rock mining, and milling. High Cr/C ratio is used in the high impact application and low to medium abrasive material such as cone crusher inlets, ball mill heads, apron feeders, and dumping pockets.

Condition:

Class II Type B produced in as-cast, Stress Relieved (SR) and heat-treated condition.