Abreco®

Wear

Plate

abreco®

Abreco® Wear Plate

Wear Plate

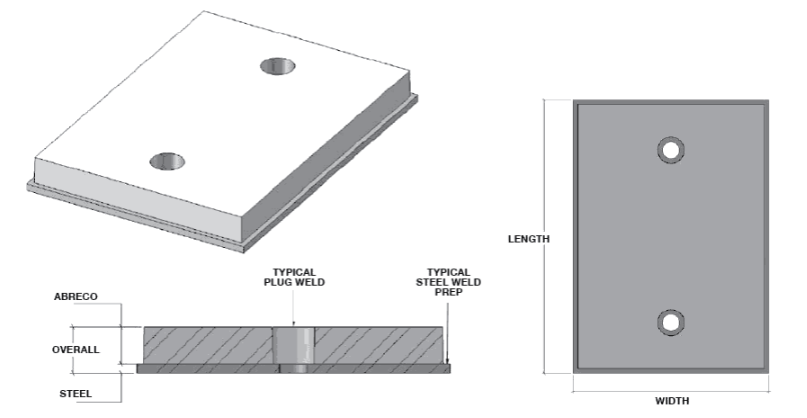

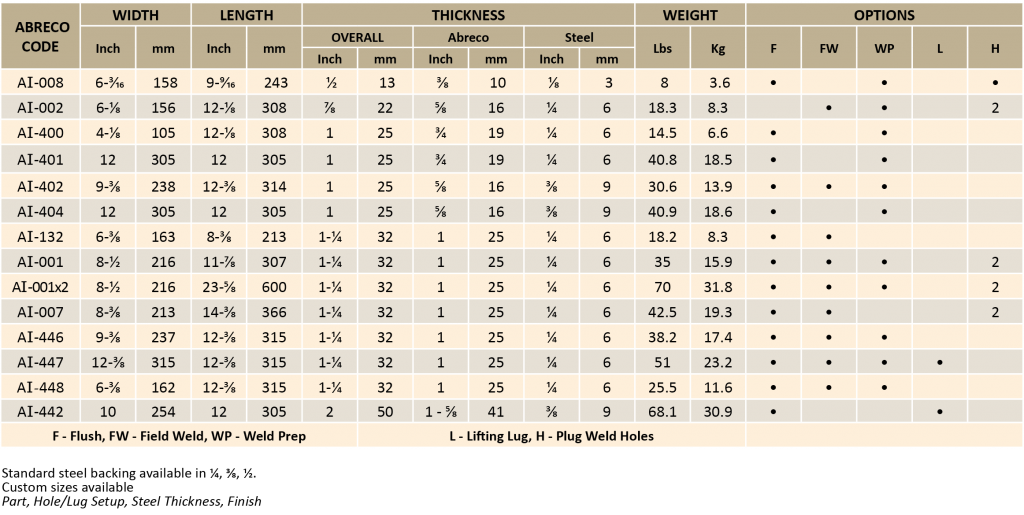

For use in fabricated, complete ready to install wear liner packages, a wide range of AbrecoPlate laminated wear plates are kept in stock consisting of varying sizes and thicknesses to meet the needs of any application.

- Wear plates can be fabricated into large Abreco® panels by welding the steel backing plates together, then profile water-jet cut to finished wear liner dimensions

- Wear plates can be installed in the same manner as any traditional wear liner, via welded studs, countersunk bolts, plug welding or direct weld